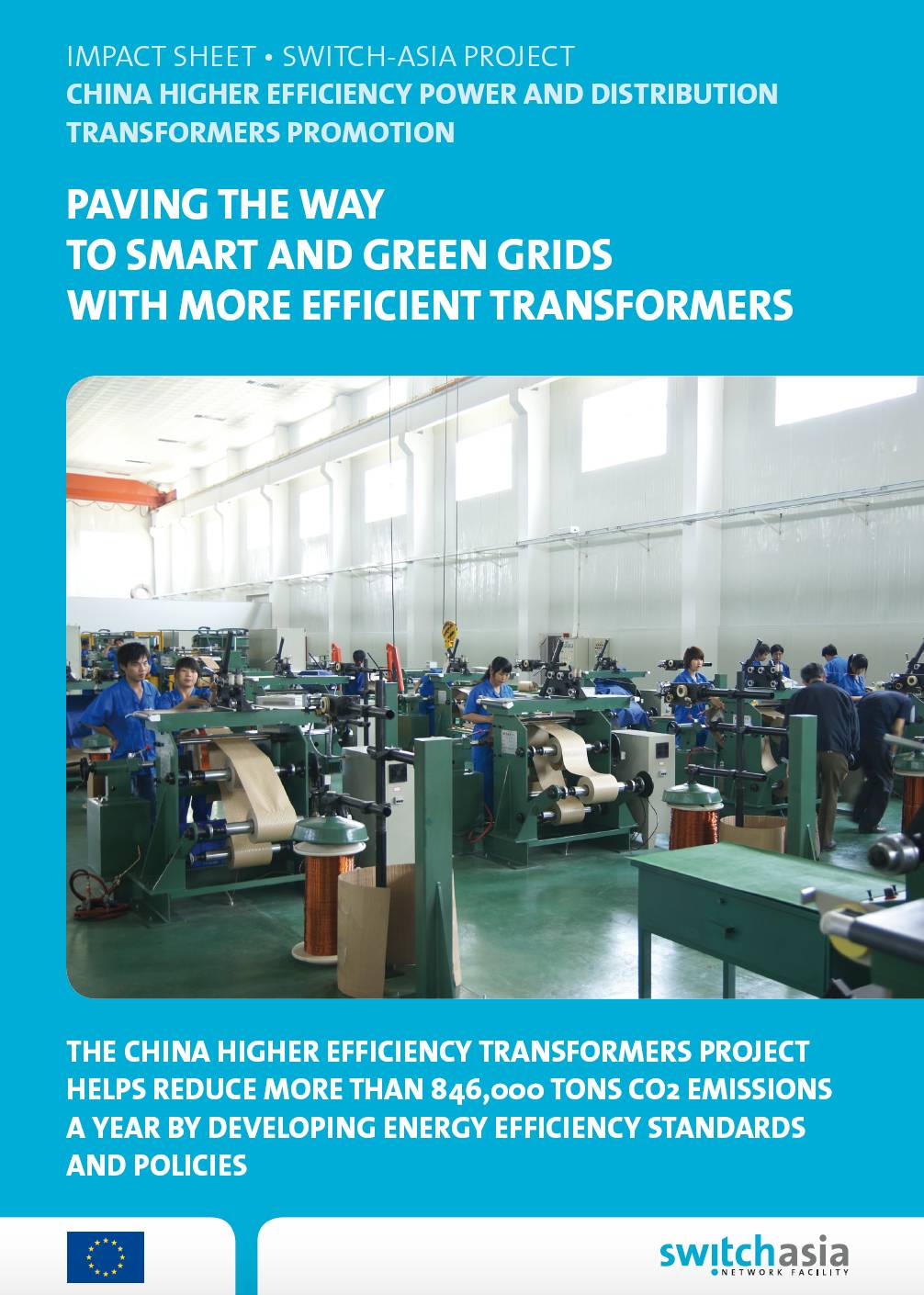

The Challenge

The annual loss of electricity in China is more than 20 billion kWh. About 30-40% of this loss derives from power transmission and distribution. Large energy intensive industries use a lot of transformers and upgrading the inefficient ones is not economical – the energy savings generated are not enough to compensate for the investment cost. Local manufacturers lack capacity to produce higher efficiency transformers. End-users do not see the advantages of using them.

The Objectives

The project sought to reduce electricity loss by increasing the market penetration of higher efficiency transformers (S11 and above), and by enlarging their market share in China.

The Way Forward

- Close partnerships were established among the policymakers, institutes, manufacturers, end-users and energy management and supervision organisations;

- Three national standards for transformers were developed: the minimum energy performance standards (MEPS), the ecodesign guidelines for manufacturers, and a total-cost owning guideline (TCO) and tool to support procurement decisions.

- The MEPS standard was submitted and will be issued officially by the government in 2013. The eco-design standard and TOC guideline were issued and effective at 2012 officially;

- The MEPS is mandatory and thus all newly installed transformers will have to comply once it is approved;

- The acceptance of the eco-design guideline by Chinese manufacturers was ensured by a closed involvement of China Electrical Equipment Industrial Association (CEEIA);

- End-users are enabled to take an informed decision by using the TCO guideline and products’ database developed by the project.

Duration:

12/2009 – 12/2012Total Budget:

EUR 781,832.95 (EU Contribution: 80%)Contact Detail:

Mr. Philip Zhang

+86-10-68042450, ext. 203

66, Nan Li Shi Road,

Beijing, 100045

China

Lead Partners