Mongolia's domestic livestock population includes 10.4 million animals, with yaks numbering around 1 million, predominantly located in six provinces. These animals are integral to the Mongolian way of life, offering a diverse array of products such as milk, fibers, cashmere, hair, meat, and hides. Yaks present fewer environmental challenges and maintenance demands compared to other livestock, making them a sustainable choice for local communities.

Historically, yak hides and skins have been primarily used for leather production, yielding materials for footwear, garments, and various other items. However, the prevalent method of mineral (chrome) tanning, along with synthetic finishing processes, poses significant environmental concerns due to its high energy and water demands, as well as the pollution from waste and effluent discharges.

In contrast, vegetable tanning and the creation of full grain vegetable leathers offer promising avenues for reducing environmental impact, aligning with principles of sustainability and eco-friendly production.

To address the numerous challenges facing Mongolia's yak leather industry including: outdated processing technologies, non-compliance with international quality standards, inefficient waste treatment infrastructure, and a shortage of skilled workers, the European Union funded SWITCH-Asia Sustainable Yak Leather (SYL) was launched to develop the production of bio-leather and the manufacture of associated bio-leather products by strengthening the capacities of the Mongolian Vegetable Tanned Yak Leather Cluster.

This cluster has dedicated itself to improving market access, embracing green technologies, and adhering to environmental policies and standards. Emphasizing Circular Economy and Extended Producer Responsibility (EPR) principles, the industry is moving towards a sustainable model that prioritizes reduction, reuse, and recycling, thereby minimizing waste and promoting circularity in line with the Sustainable Development Goal (SDG) 12: Responsible Consumption and Production and its associated targets (3: Halve global per capita food waste; 4: Responsible management of chemicals and waste; and 5: Substantially reduce waste generation).

The project has made significant improvements in refining slaughtering (and carcass dressing) operations, reducing waste and chemical usage, and streamlining the entire value chain to minimize and manage waste more effectively. These efforts not only contribute to a more sustainable industry but also enhance the appeal of vegetable-tanned yak leather to environmentally conscious consumers.

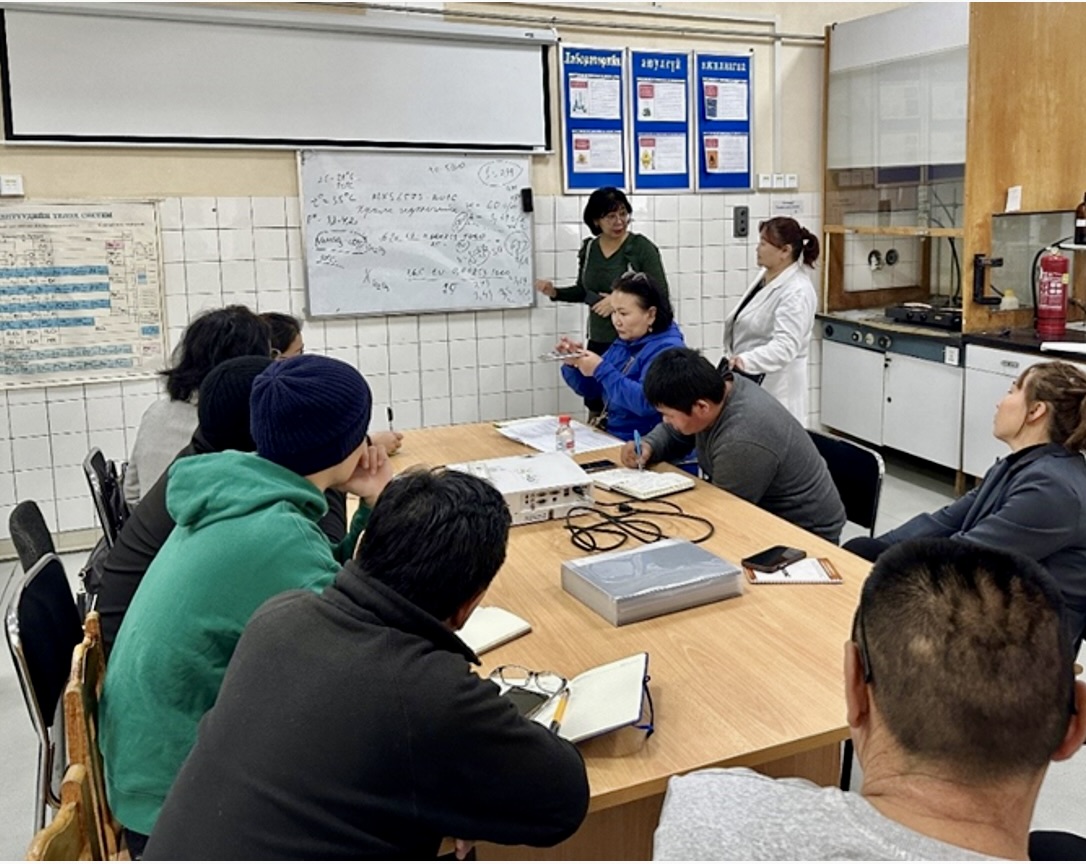

A recent initiative was the five-day training programme held from 11th - 15th December 2023, focusing on alternative processing methods that eliminate materials hindering recycling. Conducted at the Food, Agriculture, and Light Industry Research and Development Centre in Ulaanbaatar, Mongolia, the training attracted 20 participants and covered topics such as:

- Introduction to the concepts of reducing, reusing, and recycling for sustainability.

- Appreciation of the costs and consequences of not recycling.

- Appreciation of the advantages of recycling.

- Provision of information on processes and products that constrain recycling.

- Provision of information on processes and products that facilitate recycling.

- Monitoring and measuring the impacts of recycling.

Looking ahead, the project plans to offer online mentoring sessions to at least ten tanning and finishing supervisors and operators focusing on low-energy and low-emission finishing techniques. This initiative aims to improve operational efficiency and sustainability in leather production. Additionally, a comprehensive guide on implementing these eco-friendly practices will be distributed to local tanneries, accompanied by a two-day online training session to enhance process monitoring and control techniques (using up-to-date analysis and testing methods), ensuring immediate resolution of any arising issues and further advancing the industry towards greener horizons.

Photo credits: SWITCH-Asia Sustainable Yak Leather (SYL) project