In India, informal waste pickers are crucial for plastic waste collection, accounting for approximately 70% plastic waste collection. The majority of plastic waste, around 96%, is recycled by these informal workers, highlighting their importance in the waste management ecosystem. Despite their significant role, they face marginalisation and poverty due to their lack of negotiating power in the value chain and their earnings remain meagre, often below USD 4 per day, as they struggle with low margins.

To address the growing plastic waste crisis, the Indian government enacted the Plastic Waste Management Rules (PWMR) in 2016, emphasising Extended Producer Responsibility (EPR). This policy aims to hold producers, brand owners, and distributors accountable for waste management, requiring them to establish recycling systems and report to regulatory bodies. Despite these efforts, progress has been slow, partly due to the challenge of integrating the informal sector into formal value chains.

Empowering waste pickers is key to achieving a circular economy in the plastic sector. Civil society organisations like the Kashtakari Panchayat Trust (KPT) have been advocating for their rights and are instrumental in providing support, education, and training to waste pickers in Pune and Pimpri - Chinchwad.

Since 2006, the SWaCH cooperative in Pune has empowered nearly 3,500 female waste pickers to provide door-to-door waste collection services. Authorised by the Pune Municipal Corporation, it serves around 800,000 households in the city.

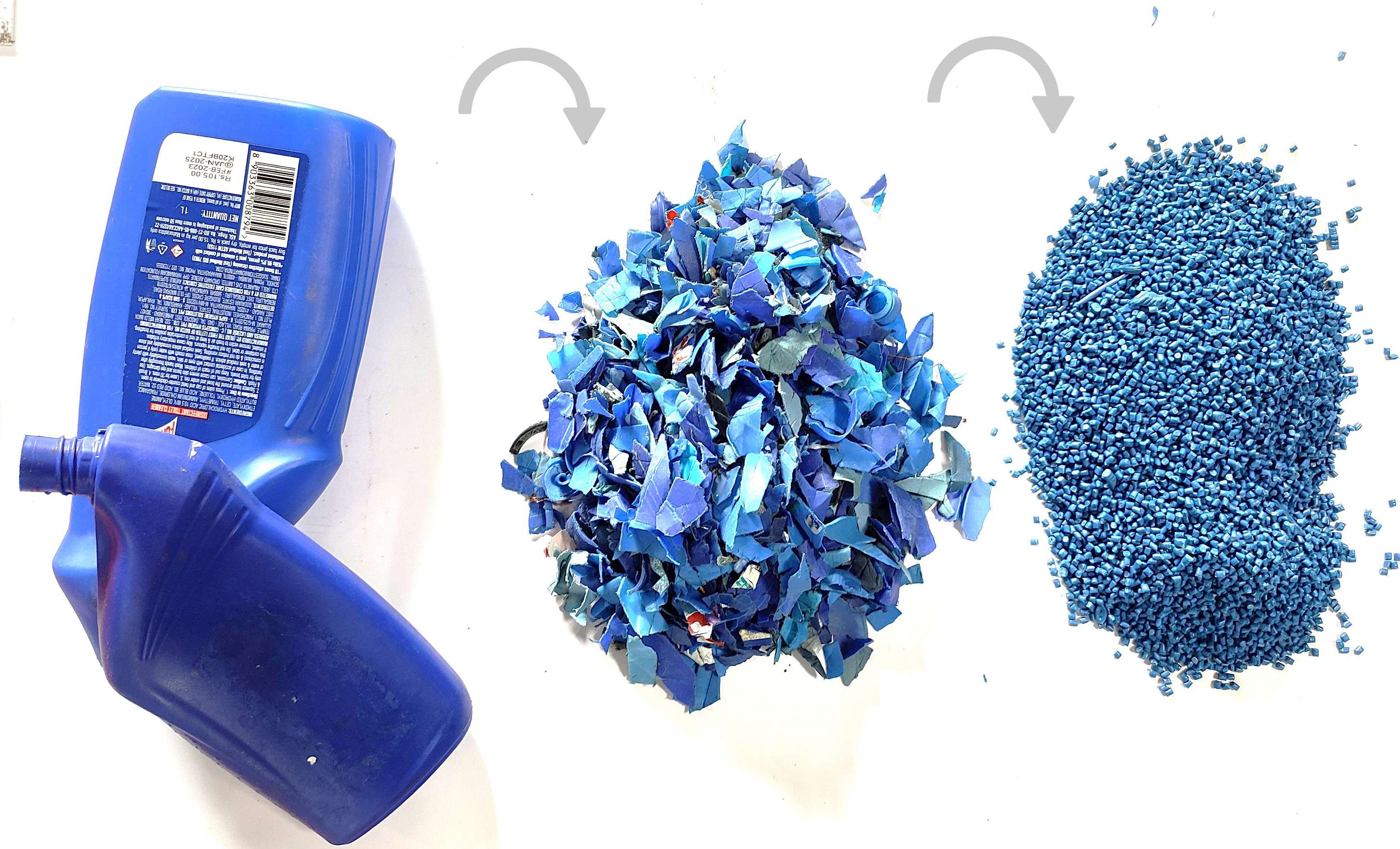

Another organisation working towards empowering waste pickers is Social Seva Initiatives (SSI). Through their activities, SSI converts collected HDPE plastic into high-value products, fostering profitable micro-entrepreneurship. Under the EU funded SWITCH-Asia Protoprint project, SSI has collaborated with KPT, SWaCH cooperative, SWaCH Plus and adelphi to empower waste pickers in Pune by converting HDPE and PP plastic waste into high-value products like HDPE and PP flakes, granules and 3D printing filament made from recycled HDPE. This innovative approach aims to make waste pickers profitable micro-entrepreneurs within the solid waste management industry. This value-added approach promises to substantially improve the livelihoods of waste pickers. Moreover, by tapping into the rapidly growing 3D printing market, this technology offers sustainability benefits and the potential for a closed-loop recycling system, further enhancing the value and innovation in material recycling.

Protoprint benefits and impact

The Protoprint technology harbours the capacity for a substantial and profound impact such as:

- High Impact on SDGs: 1- No poverty; 2- Zero Hunger; 3- Good Health and well-being; 4- Quality Education; 5- Gender equality; 6-Clean water and sanitation; 8- Decent work and economic growth; 9- Industry innovation and infrastructure; 10- Reduced inequalities; 11- Sustainable cities and communities; 12-Responsible consumption and production; 13- Climate action; 16- Peace and justice; 17- Partnerships for goals.

- Social transformation: Empowering women waste-pickers through skill development for sustainable livelihoods, training and upskilling of nearly 1000 waste pickers, and creation of SHGs.

- Environmental benefits: Promoting Circular Economy by converting HDPE waste into high value products - 3D print filament, reducing reliance on virgin plastic, end to end recycling of Punes plastic waste, aiding the municipal corporation in developing model EPR strategies, making Pune a recycling innovation hub and learning centre, exemplary urban planning, development of state-of-the-art recycling parks, GHG emissions mitigation.

- Economic empowerment: Creating linkages between waste pickers and businesses, enhancing profitability through value-added products, creation of green jobs in waste management.

A replicable and scalable business model

Under the EU SWITCH-Asia Protoprint project, a sustainable, replicable and scalable business model in the form of 2 units has been set up in Pune. This resulted in the establishment of a decentralised network of processors that transforms plastic waste into plastic flakes which can be either sold directly, processed into pellets/granules or further processed into 3D printing filament. HDPE and PP waste is sourced from 3 scrap shops, which buy plastic waste directly from waste pickers. The HDPE and PP waste from these scrap shops is channelled towards the 2 processing units. At the processing unit 1, two separate processes take place - flaking of PP and HDPE (separated to maintain purity of flakes) and granulation. At the second unit the 3D print filament manufacturing from HDPE flakes takes place along with the actual 3D printing. The flakes and further processed pellets/granules of PP and HDPE (intermediate products) will be sold into the market, and the high-quality HDPE flakes can result in further value-addition through conversion into 3D printing filament.

Moving Forward

Under the Protoprint Project, there are a wide range of initiatives and endeavours that are currently under focus:

- R&D and quality improvements of the recycling process to make high quality recycled plastic.

- Implementation of statutory and administrative requirements of setting up recycling units.

- Training of waste pickers on recycling technology.

- Connecting with market for offtake of recycled plastic and 3d print filament.

- Connecting with government institutions to support the set-up of a waste picker enterprise that will run the recycling unit.

- Certifications and assessments of the value chain.

The project aims to establish a model EPR policy for the city of Pune which stands strongly on the foundation of a Circular Economy. This will be led by the waste picker collective which will operate the units independently. The formalisation of collection centres (scrap shops) is required and will be a policy level implementation. This will also be beneficial for the waste picker collective in their operations of buying plastic from scrap shops. The project targets generation of Green Jobs as listed by the SCGJ (Skill Council for Green Jobs). Within the project period, Protoprint will dig deep into the 3d printing, international and Indian markets. This intense study will result in 2 high level route- to- market reports which will bolster the scope and understanding of the new booming 3d printing industry. In order to further understand the impact of this project, a life cycle analysis will be carried out to understand the implications on the climate and life cycle costing, as well as financial sustainability. Involvement with various key stakeholders, governmental agencies and international organisations will result in Policy briefs and round table conferences which will be organised in the coming months

Photo credits: EU SWITCH-Asia Protoprint project